Analytical precision in life science applications—like DNA Sequencing, PCR, Flow Cytometry and Imaging —depends on optical filters’ capacity to isolate specific wavelengths and fluorescence signals and facilitate the distinction between different biological structures and molecules through selective light filtering. Ultimately, driving disease detection, treatment and research efforts.

Medical inventions such as medical lasers, imaging techniques, and wearable devices are the tools that bring personalized medicine’s promises to life. Behind their diagnostic and individualized therapeutic capabilities lie the operational benefits of optical filters. They power medical lasers by refining the wavelength for targeted tissue interaction, improve imaging techniques by expanding contrast and clarity, and augment wearable devices’ accuracy as they filter ambient light to make signals more reliable for monitoring health statuses.

Analytical applications are vital for human health, as they are among scientists’ best tools for understanding environmental impacts. Optical filters facilitate precise environmental monitoring and molecular spectroscopy by selectively allowing wavelengths corresponding to specific substances, streamlining accurate detection and quantification.

Customized Solutions for Unique Applications

The critical importance of filters in life science instrumentation development can easily be minimized without a firm grasp of how things work behind closed operational doors. Bringing an instrument to the life science market requires deep technical prowess and inventiveness.

However, even the most radically transforming innovation does not stand a chance of success if several moving parts are not running smoothly. The specifications of an instrument are precise, and the operational details in the development cycle demand a degree of accuracy and performance that can only be realized after extensive testing and prototyping. But here is the issue. It is not an easy task to find the components that will power an instrument from an off-the-shelf (OTS) option in a catalog.

Filters are critical elements of an instrument, and developers do not want to modify them later in the development cycle. Testing is required. Nevertheless, cost can become a problem. Some filter suppliers offer large batches or extensive production timelines for developers to finetune their instruments, which delays product launches and becomes a competitive hurdle.

Comprehensive Filter Portfolio for Life Science Innovators

Optical filters serve distinct functions, so their selection process demands preciseness.

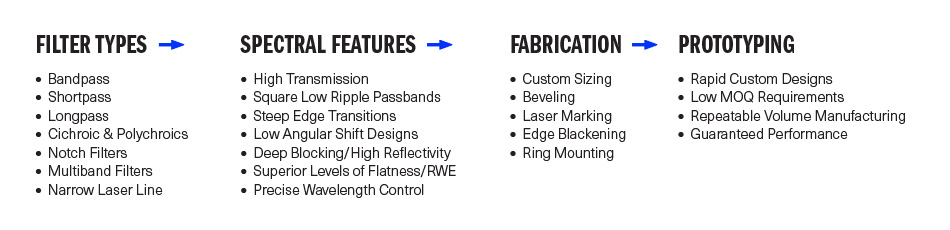

The needs of instrument developers and application uses are also broad, so we at Coherent have built a purposeful and comprehensive portfolio of optical filters that includes:

Bandpass Filters: Isolate specific wavelengths, vital for analytical and imaging applications.

Shortpass and Longpass Filters: Enable wavelength cutoffs, permitting only shorter or longer wavelengths to pass.

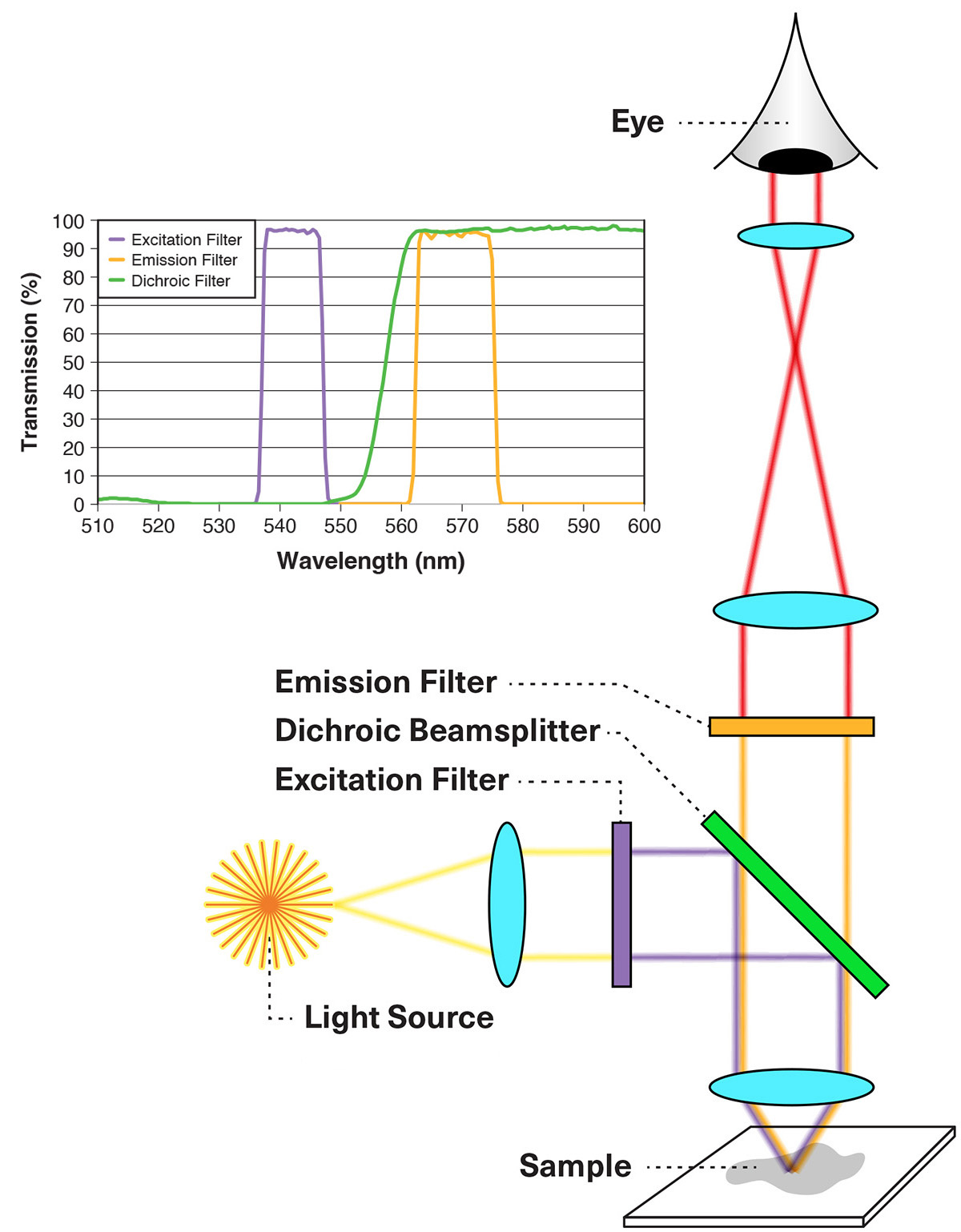

Dichroic and Polychroic Filters: Facilitate beam splitting, commonly used in fluorescence microscopy to direct light into different paths.

Notch Filters: Reject targeted light, necessary in applications that block specific wavelengths while transmitting others.

Multiband Filters: Support multi-fluorophore applications, detecting multiple fluorescence signals at once.

Narrow Laser Line Filters: Ensure precise wavelength selection, isolating specific laser lines needed for high-precision tasks.

Instrumentation developers need a flexible partner who can facilitate filter selection along with providing extensive testing for optimal performance.

Cutting-Edge Coating Platforms: Delivering High-Performance Filters at Scale

With our full portfolio capability, designs can be aligned with other optical components and tested at a system level. Our full optical fabrication capabilities include wafer dicing, coring, wedging, and polishing.

Life science instrument developers can take advantage of our MS, IBS, IAD, and EB coating technologies to push the boundaries of optical performance. IBS coatings set the standard for durability and precision, while our proprietary MS platforms deliver comparable IBS quality and performance often at lower costs, providing developers with budget-friendly options without compromising performance.

Our massive coating capacity is also supported by full vertical integration capabilities. Precision and custom mounting is critical for performance – whether a simple single filter mount to more complex cubes, sliders, or custom subassemblies. Coherent is a leader in opto-mechanical-electrical design from prototyping to full volume production.

Cutting-edge coating capabilities translate to filters delivering precision-based measurements, high spectral performance, sharper imaging, more sensitive detection, and improved data quality across multiple life science applications, from Bioanalytical to Medical platforms.

Automated optical metrology guarantees 100% measurement with full traceability, in-house reliability, and environmental testing. Our integrated model makes system-level testing—even using customer-specific platforms—possible.

Customer Service QQ

Customer Hotline:

Technical Supports