Updated:2025-03-13

Views:1758

WeChat

WeChat

QQ

QQ

Online Service

Online Service

User 's Manual

User 's Manual

Hygienic compact refractometer PR-43-AC Suitable for installation in 2.5 "and smaller pipes. The refractometer is mounted in a bent tube. With sanitary clamps or Varivent® connections, it can be mounted either directly on the corner of the bend or on the circulation tank.

Sanitary probe type refractometer PR-43-AP Suitable for installation on large pipelines, storage tanks, digesters, moulders and can withstand high temperatures up to 150°C (300 °F). The refractometer is mounted on the pipe or container through a 2.5 "or 4" sanitary grade clamp.

Sanitary flush type refractometer PR-23-APTInstall on cooking tanks, cooling crystallization tanks and other sanitary grade containers with scrapers or stirrers. The refractometer is mounted with the flange at the bottom of the APV tank or on a pipe or tank with a steam jacket.

A variety of user interface styles are available: from rugged multi-channel industrial computers to compact lightweight interfaces and Web interfaces, users can choose their preferred way to access and use refractometer measurements and diagnostic data. The refractometer user interface can be installed locally in the field, in a remote control room, or both (by connecting several user interfaces in a network).

Consistent calibration of each sensor: Sensors are freely interchangeable.

The refractive index (nD) measurement ranges from 1.3200 to 1.5300, corresponding to 0 to 100 Brix.

Through the 3A health certification, to meet the high standards of food production health requirements.

Support Clean in Place (CIP) and Sterilisation in place (SIP) processes and facility cleaning.

Full digital system: particles and bubbles do not affect operation or accuracy.

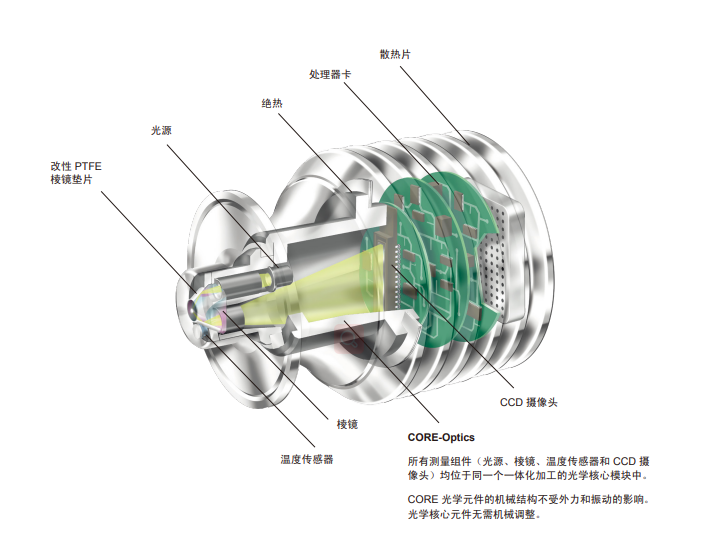

CORE-optics Optics: no drift, no recaliphation, no mechanical adjustment.

The PR-43-A refractometer has a built-in Web server that displays the instrument home page. Users can set parameters, verify and obtain instrument monitoring and diagnosis information through the homepage.

Process temperature: -40°C... 130°C (compact); To 40 ° C... 150°C (probe type).

Built-in Pt1000, fast temperature measurement and automatic temperature compensation work.

Users can easily complete field instrument verification with standard refractive index liquids to meet their own quality assurance system requirements.

Provides Enhanced Safety (Ex e) certification for installations in hazardous areas

Customer Service QQ

Customer Hotline:

Technical Supports