Updated:2025-03-13

Views:2610

WeChat

WeChat

QQ

QQ

Online Service

Online Service

Optics and windows experty crafted with ideal performance and durability tolerances for modern defense technologies including targeting, ranging, night vision, communication, and directed energy weapons systems.

Capabilities

High laser damage threshold coatings

Substrate polishing and preparation, process control, and coating designs

Class 1000/100 Assembly Cells, Sub-Cells

Sub-Micron, Traceable Metrology & Testing

Beam Steering

Ultra-Fast & High Power Lasers

Display Windows

Sensors

Anti Reflection Coatings

Broadband and custom-tuned anti-reflection (AR) coatings ensure high light transmission through optical systems and mitigate ghost effects, especially with multiple surfaces. AR coatings can be incorporated with spectral filters and are commonly used on optics, sensors, and display windows.

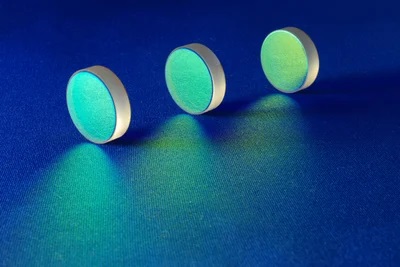

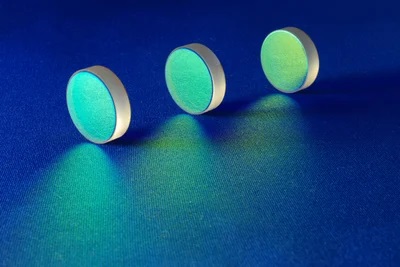

Laser Line High Reflectors

High-power thin film mirror coatings are central to Torrent's capabilities. Laser line mirrors reflect light with high efficiency and minimal scattering or absorption. We collaborate with external institutions to regularly certify the performance of our laser damage threshold. At Torrent, we offer laser line high reflectors at 99.995% from visible to NIR & 99.9% UV.

Harmonic Separators

Dichroic beamsplitters are called harmonic separators to reflect one wavelength while transmitting the other. The front surface has a beamsplitter coating, while the back surface is AR V-Coated at wavelengths of transmitted light. We offer high reflectance from both S- and P-polarized light.

Wavelength Configurations for Nd: YAG Laser Applications

1064nm Reflected, 532nm Transmitted

532nm Reflected, 1064nm Transmitted

355nm Reflected, 532 and 1064nm Transmitted

266nm and 355nm Reflected, 532 and 1064nm Transmitted

2、Front Surface Coatings

The front surface of the UV-fused silica substrate is covered with a reflective beamsplitter, and the back surface is coated with an antireflection (AR) V-coating for the transmitted wavelength. Both coatings are designed for an incidence angle of 45 degrees (AOI). Although it is also possible to reverse the propagation direction of the beams incident on each beamsplitter to combine light instead of dividing it, each beamsplitter has a part number and an arrow indicating the preferred propagation direction etched on its edge.

3、Back Surface Coatings

The interaction of light reflected from the optic’s front and back surfaces results in unwanted interference effects (such as ghost pictures), which the AR V-coated back surface helps to minimize. When applying an AR coating to the back side of the beamsplitter, this proportion decreases to an average of less than 1% for the coating’s full operating range. Typically, 4% of light incident at 45 degrees on an untreated substrate will be reflected. Each beamsplitter contains a 30 arcmin wedge; in addition to this feature, thus the amount of light reflected off this AR V-coated surface will diverge.

Beamsplitters

Plate beamsplitters have a front surface that is coated, which controls the beam-splitting ratio, and a back surface that is wedged and AR coated, which reduces interference and ghosting effects.

Pellicle beamsplitters offer superior wavefront transmission qualities while preventing ghosting and beam offset. You can choose between polarizing and non-polarizing types of our cube beamsplitters. For use with our lens tube and cage systems, the pellicle and cube beamsplitters can be purchased pre-mounted in cubes.

Dichroic beamsplitters have wavelength-dependent beam-splitting characteristics. They help mix and split different-colored laser beams.

1、Polarizing Beamsplitters

Polarizing beamsplitters, by design, divide light according to its polarization state rather than its wavelength or intensity. In semiconductor or photonics instrumentation, polarizing beamsplitters transmit p-polarized light while reflecting s-polarized light. Optical isolators use polarizing beamsplitters to stop feedback-caused harm. Depending on the configuration, polarizing beamsplitters are commonly made at angles of 0 degrees or 45 degrees with a 90 degrees separation of the beams.

Polarizing beamsplitters are available in various designs, such as plate, cube, or lateral displacement. For optimal performance, when utilized with ultraviolet, visible, or infrared wavelengths, plate beamsplitters come in various sizes. Applications requiring robustness, easy mounting, or system integration are perfect for cube beamsplitters. The incident beam will be separated into two displaced parallel beams using lateral displacement beamsplitters. In addition, polarizing beamsplitters are available for popular laser wavelengths or wavelength ranges.

2、Non-Polarizing Beamsplitters

Light emitted is split by non-polarizing beam splitters at a predetermined ratio regardless of polarization. Beamsplitters, also called non-polarizing beamsplitters, are made to divide light without changing their S- and P-polarization states. Non-polarization Beamsplitters are frequently used in interferometry, life science instrumentation, and laser beam modification, among other applications. Non-polarizing beamsplitters are available in various shapes, such as plate, cube, and lateral displacement.

Customer Service QQ

Customer Hotline:

Technical Supports