Updated:2025-03-13

Views:2577

WeChat

WeChat

QQ

QQ

Online Service

Online Service

Datasheet

Datasheet

The Model 1531 is an industrial-grade surface mount MEMS DC accelerometer that is specifically designed for use in higher-temperature applications. Its performance specifications are virtually identical to those of the SDI Model 1521, yet with the further incorporation of higher-temperature materials. Each Model 1531 MEMS DC accelerometer is nitrogen damped, hermetically sealed, carefully tested in a climate chamber environment, and undergoes rigorous temperature conditioning protocols to ensure its continued reliable operation in temperatures up to +175°C.

Each miniature, hermetically sealed package combines a MEMS capacitive sense element for DC measurement and a custom integrated circuit that includes a sense amplifier and differential output stage. This design ensures that the device remains relatively insensitive to temperature changes and gradients. Each package undergoes individual testing, programming, and calibration by SDI, and is marked with a serial number on its top and bottom surfaces for easy traceability. Additionally, an optional calibration test report (1531-TST) is available for every unit, displaying the accelerometer's measured bias, scale factor, linearity, operating current, and frequency response specifications.

Low Noise: 12 μg/rootHz Typical for ±5g Full Scale Versions

-55 to +175°C Operation

Responds to frequencies from zero (DC) to 2000+ Hz

High Stability and Durability

±4V Differential Output

+5 VDC, 5 mA Power (Typical)

Integrated Sensor & Amplifier

Internal Temperature Sensor

Nitrogen Damped & Hermetically Sealed

Serialized for Traceability

RoHS Compliant

| g Range | Sensitivity, Differential | Frequency Response (Typ, -3 dB) | Frequency Response (Typ, 5%) | Frequency Response (Min, -3 dB) | Output Noise, Differential (RMS, Typ) | Max. Mechanical Shock (0.1 ms) |

| G | mV/g | Hz | Hz | Hz | μg/(root Hz) | g (peak) |

| ±5 | 800 | 0 – 800 | 0 – 420 | 0 – 400 | 12 | 2000 |

| ±10 | 400 | 0 – 1100 | 0 – 700 | 0 – 660 | 18 | 5000 |

| ±25 | 160 | 0 – 1750 | 0 – 1300 | 0 – 1050 | 25 | 5000 |

| ±50 | 80 | 0 – 2100 | 0 – 1600 | 0 – 1400 | 50 | 5000 |

| ±100 | 40 | 0 – 3000 | 0 – 1700 | 0 – 1700 | 100 | 5000 |

| ±200 | 20 | 0 – 3600 | 0 – 1900 | 0 – 2100 | 200 | 5000 |

| ±400 | 10 | 0 – 4200 | 0 – 2000 | 0 – 2400 | 400 | 5000 |

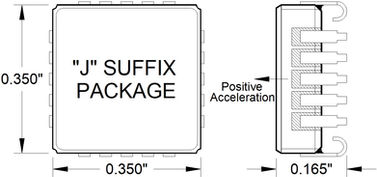

The Model 1531 sensitive axis is perpendicular to the bottom of the package, with positive acceleration resulting from a positive force pushing on the bottom of the package. The seismic center is located on a centerline through the dual sense elements and halfway between them.

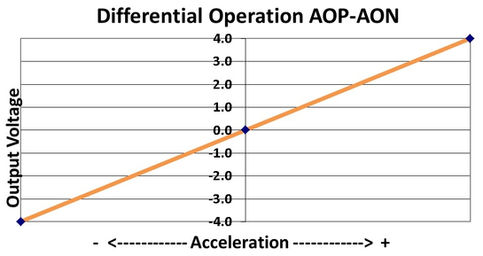

The Model 1531 produces a differential ±4 volts output voltage, the value of which varies with acceleration as shown in the figure. The seismic center is located on a centerline through the dual sense elements halfway between them. Any errors due to rotation about this point are effectively cancelled by the internal electronics.

Two reference voltages, +5.0 and +2.5 volts (nominal), are required; scale factor is ratiometric to the +5.0 volt reference voltage relative to GND, and both outputs at zero acceleration are nominally the same as the +2.5 volt input.

All Models: Unless otherwise specified, Vs=+8 to +32 VDC, TC=25°C, Differential Mode. Span = ±g range = 8000 mV.

Note (1): For 2g thru 50g only; 100g and greater versions are tested and specified from -65 to +65g.

NOTICE: Stresses greater than those listed may cause permanent damage to the device. These are maximum stress ratings only. Functional operation of the device at or above these conditions is not implied.

PACKAGE DIMENSIONS

Customer Service QQ

Customer Hotline:

Technical Supports