Updated:2025-03-13

Views:1695

WeChat

WeChat

QQ

QQ

Online Service

Online Service

User's Manual

User's Manual

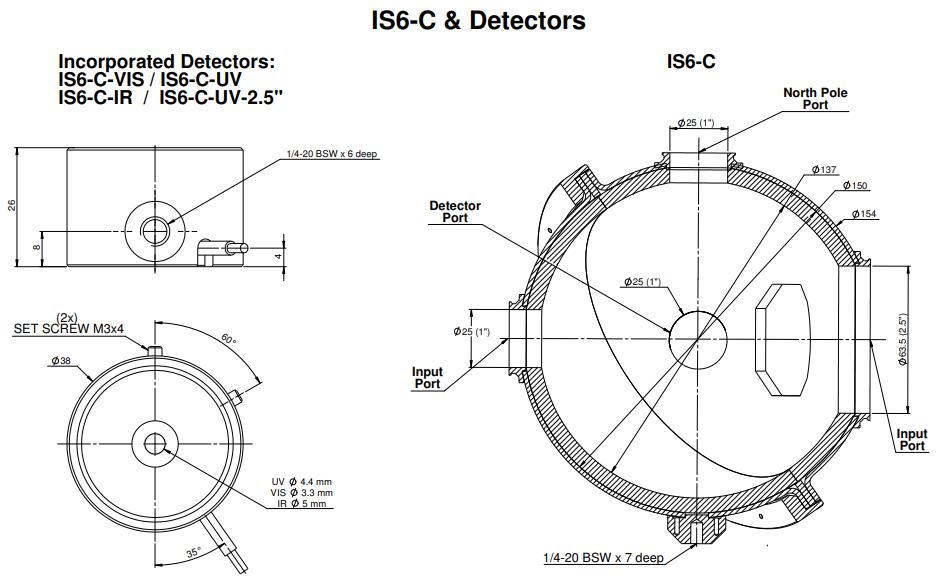

The IS6-C-IR is a 6” integrating spheres (5.3” inside) with a Germanium detector for use with collimated (C) beams. The IS6-C-IR comes with a IR detector, is calibrated from 700 to 1800nm and can measure up to 30W.

| Aperture | Ø25mm |

| Spectral Range | 700-1800nm |

| Power Range | 20μW-30W |

| Dimensions | Ø154 (mm) |

| Max Pulse Energy | 0.3mJ |

| Max Average Power Density | 1 kw/cm² |

| Max Average Power | 30W |

| Max Beam Divergence | ±15 deg |

| Sensitivity to Beam Size | ±1% |

Influence of Wavelength on Measurement Accuracy

All absorbers used in power/energy measurement are not completely flat in spectrum, that is, their absorption varies with wavelength. For this reason, Ophir measurement sensors are usually calibrated at more than one wavelength. If the absorption only changes slightly with the wavelength, then the wavelength areas less than 600nm and more than 600nm will be defined and calibrated in these areas. In this case, the measurement error between the wavelength calibrated by the device and the measured wavelength is assumed to be within the calibration error range of the main wavelength. If the absorption difference between the nearest calibrated wavelength and the measured wavelength is greater than 1-2%, add the error of the wavelength in this area to the specification, or calibrate on the continuous calibration curve covering all wavelengths in this area.

Influence of linearity on measurement accuracy

The linearity of Ophir sensors is always given in the published specifications for thermal sensors and pyroelectric sensors, and the expected error caused by nonlinearity will be added to the basic calibration error. Note that for thermal sensors, the linearity error is typically+/- 1% or any value in a specific sensor specification. For photodiode sensors, the linearity error is not published, but it is always less than ± 1% unless very close to the maximum power. If the power level is lower than 70% of the maximum power of the photodiode sensor, the linearity will be within ± 0.5%.

Customer Service QQ

Customer Hotline:

Technical Supports