Updated:2025-03-13

Views:2131

WeChat

WeChat

QQ

QQ

Online Service

Online Service

Datasheet

Datasheet

SDI’s Models 2460 and 2466 Low Cost Three-Axis MEMS DC Accelerometers are rugged plug-and-play measurement devices that provide reliable performance in most zero-to-medium frequency commercial and industrial applications, particularly where extremely low noise, and long-term stability are absolute requirements. The 2460 includes a 3-foot integrated cable and are operationally identical to the 2466, which features a connector for easily customized cable lengths and positions.

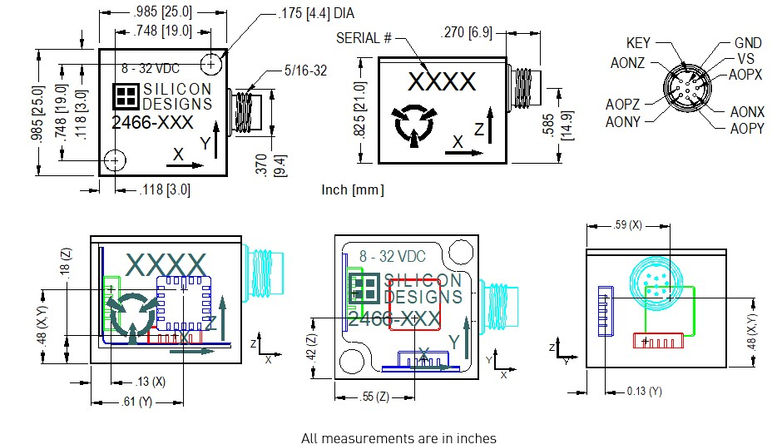

Each SDI 2460 and 2466 triaxial accelerometer features three orthogonally mounted low noise accelerometers within a single, rugged, epoxy sealed, anodized aluminum case. Onboard voltage regulation and an internal voltage reference eliminate the need for precision power supplies. They are relatively insensitive to temperature changes and gradients. Individual axis directions are marked on the case with positive acceleration defined as acceleration in the direction of the axis arrow. The robust, anodized aluminum case is epoxy sealed and can be mounted easily via two screws, an adhesive, or by attaching a magnet.

Low Noise: 10 μg/rootHz Typical for ±2g Full Scale Versions

-55 to +125°C Operating Temperature Range

Acceleration and Vibration Sensing Across Three Orthogonal Axes

Excellent Long-Term Stability

Flexible +8 to +32 VDC Power

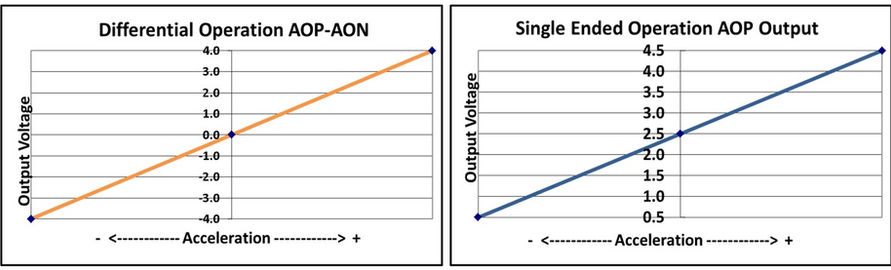

±4V Differential Output or 0.5V to 4.5V Single Ended Output

Responds to frequencies from zero (DC) to 2000+ Hz

Low Impedance Outputs Support up to 2000 Feet of Cable

Simple Eight (8) Wire Connection, Choice of Integrated Cable or Connector

Rugged Anodized Aluminum Case

Fully Calibrated and Serialized for Traceability

| g Range | Sensitivity, Differential | Frequency Response (Typ, 3 dB) | Frequency Response (Min, 3 dB) | Frequency Response (Typ, 5%) | Output Noise, Differential (RMS, Typ) | Max. Mechanical Shock (0.1 ms) |

| G | mV/g | Hz | Hz | Hz | μg/(root Hz) | g (peak) |

| ±2 | 2000 | 0 – 525 | 0 – 300 | 0 – 250 | 10 | 2000 |

| ±5 | 800 | 0 – 800 | 0 – 420 | 0 – 400 | 15 | 2000 |

| ±10 | 400 | 0 – 1100 | 0 – 660 | 0 – 700 | 23 | 5000 |

| ±25 | 160 | 0 – 1750 | 0 – 1050 | 0 – 1300 | 38 | 5000 |

| ±50 | 80 | 0 – 2100 | 0 – 1400 | 0 – 1600 | 60 | 5000 |

| ±100 | 40 | 0 – 3000 | 0 – 1700 | 0 – 1700 | 121 | 5000 |

| ±200 | 20 | 0 – 3600 | 0 – 2100 | 0 – 1900 | 243 | 5000 |

| ±400 | 10 | 0 – 4200 | 0 – 2400 | 0 – 2000 | 475 | 5000 |

SDI Models 2460 and 2466 MEMS DC Accelerometers provide optimal performance when they are connected to instrumentation in a differential configuration using both the AOP and AON output signals, but they also support single ended operation for complete flexibility.

These Accelerometers produce differential analog output voltage pairs (AON & AOP) which vary with acceleration. The signal outputs are fully differential about a common mode voltage of approximately 2.5 volts. At zero acceleration, the output differential voltage is nominally 0 volts DC; at ±full scale acceleration, the output is ±4 volts DC, respectively, as shown in the figure (below). The output scale factor is independent from the supply voltage of +8 to +32 volts.

When a differential connection is not possible, SDI recommends connecting the accelerometer to instrumentation in single ended mode by connecting AOP and GND to the instrumentation and leaving AON disconnected. Keep in mind that the signal to noise ratio is reduced by half for a single-ended vs. a differential connection.

All Models: Unless otherwise specified, Vs=+8 to +32 VDC, TC=25°C, Differential Mode. Span = ±g range = 8000 mV.

Note (1): For 2g thru 50g only; 100g and greater versions are tested and specified from -65 to +65g.

NOTICE: Stresses greater than those listed may cause permanent damage to the device. These are maximum stress ratings only. Functional operation of the device at or above these conditions is not implied.

SDI Model 2460

SDI Model 2466

Customer Service QQ

Customer Hotline:

Technical Supports