Updated:2025-03-13

Views:1857

WeChat

WeChat

QQ

QQ

Online Service

Online Service

User's Manual

User's Manual

2A-BB-9 is a very sensitive laser power/energy sensor with very low noise and drift. It has a 9.5mm aperture. It can measure from 20µW to 2W and from 10µJ to 2J. It is spectrally flat and covers the spectral range from 0.19 to 20 µm. The sensor comes with a 1.5 meter cable for connecting to a meter or PC interface.

| Absorber Type | Low power broadband |

| Aperture | Ø9.5mm |

| Spectral Range | 0.19-20µm |

| Power Range | 20µW-2W |

| Energy Range | 20µJ-2J |

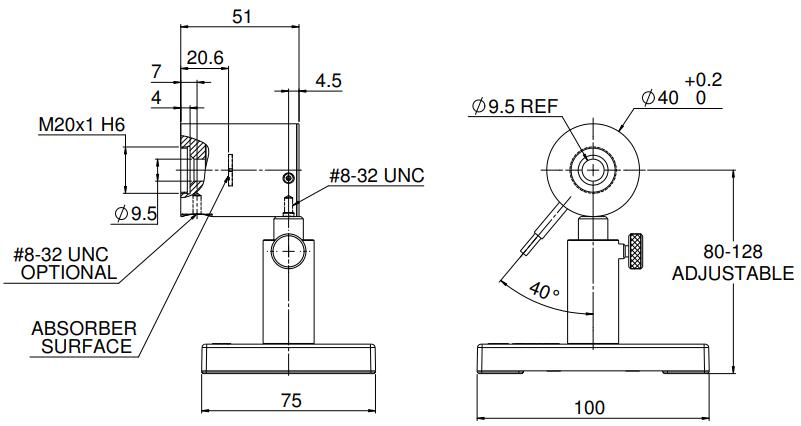

| Dimensions | Ø40 W x 51 D (mm) |

| Max Pulse Energy | 2J |

| Max Average Power Density | 1kW/cm² |

| Response Time | 1.8 s |

| Max Energy Density (for <100ns) | 0.3J/cm² |

| Max Energy Density (for 2ms) | 2J/cm² |

| Max Average Power | 2W |

Must a specific sensor be used only with the instrument used when ordering?

Ophir instruments and sensors are calibrated independently. Each instrument has the same sensitivity as the other instrument, and the error is about 2%. Each sensor is calibrated independently of a specific instrument, and its calibration information is contained in the DB15 plug. When the sensor is connected to the instrument, the instrument will read and interpret this information. Since the accuracy of the sensor is usually+/- 3%, the additional 0.2% error that may result from inserting different instruments can be ignored, so it does not matter which calibration instrument is used for a specific calibrated sensor.

Does the injury threshold depend on the power level?

The damage threshold of the thermal sensor really depends on the power level, not just the power density, because the sensor disk itself will become hotter at high power. For example, the damage threshold of Ophir broadband coating may be 50KW/cm2 at 10W but only 10KW/cm2 at 300W. Ophir's damage threshold specification is always given for the maximum power used by a particular sensor.

Does the laser measurement depend on the distance from the laser to the sensor?

Theoretically, the beam is completely parallel and suitable for the aperture of the sensor, so there should be no difference in distance. However, if you do see such distance dependency, one of the following effects may occur:

If a thermal power sensor is used, it may actually measure the heat of the laser itself; When very close to the laser, the thermal sensor may "feel" the heat of the laser itself. However, unless the light source is weak and the heat source is strong, this will not continue to have an effect over a distance of more than a few centimeters.

Beam geometry the beam may not be parallel and may diverge. In general, the lower intensity flank of the beam has a greater divergence than the main part of the beam. These may lose the aperture of the sensor as the distance increases.

If you are using a diffuser based pyroelectric sensor to measure pulse energy: you may find that when you start to move the sensor close to the laser and away from it, the reading drops sharply (usually about 6%) cm in the first few times. This may be caused by multiple reflections between the diffuser and the laser device, which may cause incorrect readings at close distances. It should be at least 5 cm back from the light source, and more if the beam is not too divergent.

Customer Service QQ

Customer Hotline:

Technical Supports