Updated:2025-03-13

Views:1749

WeChat

WeChat

QQ

QQ

Online Service

Online Service

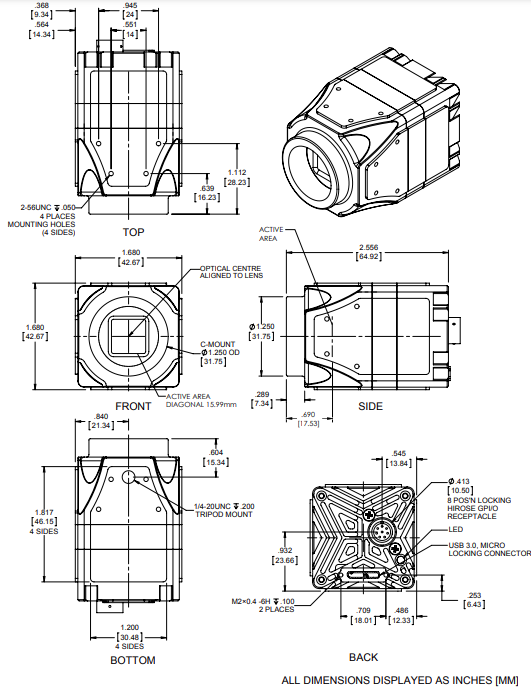

12.5mm x 10.0mm active area with an effective 60µm pixel pitch

Adjustable Gain levels and programmable electronic shutter

BeamGage Standard or Professional software included

USB 3.0 Phosphor Coated Large Format Silicon CCD High Resolution Camera with BeamGage

| Wavelengths | 1440-1605nm |

| Beam Sizes | 600μm - 9.8mm |

| Interface | USB 3.0 |

| Sensor Type | Phosphor-Coated Silicon CCD |

| Compatible Light Sources | CW, Pulsed |

| Active Area | 12.5mm x 10.0mm |

| Elements | 2752 x 2192 |

| Effective Pixel Pitch | 50μm |

| Dynamic Range | ~30 dB |

| Frame Rate at Full Resolution | 27 fps |

| Compliance | CE, UKCA, China RoHS |

Camera Image Quality – We frequently get asked about image quality as it relates to dead or bad pixels in the imager array. These questions most generally fall into one or more of these categories. Will my camera have any bad pixels? Do bad pixels affect my laser profile measurement? Can bad pixels be corrected? If I have some bad pixels what can I do about it? Will my camera performance change over time? All and more of these concerns are explained in our Camera Defects Policy document.

Camera Defects PolicyOphir-Spiricon, LLC (OSL) is a supplier of laser beam analysis tools that employ commercial-industrial solid-state cameras. OSL attempts to supply cameras with as few pixel defects as possible. OSL tests for and corrects defective pixels that may have an adverse effect when used for its intended purpose. OSL does not guarantee that a supplied camera will be defect free, or that they will remain defect free during its normal lifetime and under normal use.

It is not uncommon for modern megapixel camera imagers to develop point defects as they age, even when not subjected to abuse. Imagers without windows often experience point defects at rates typically greater than imagers with their cover glass left in place. Point defects can also appear more frequently when operating at higher rather than lower ambient temperatures, and higher relative humidity. Such defects can occur even when the camera is in storage and not being used.

Cameras supplied by OSL will be certified for use in laser beam analyzer applications. When defects occur, the ability to make certain measurements under certain conditions may be compromised. However, depending upon the nature of the defect, most measurement can still be performed without loss of accuracy. In some instances the effects of defects can be eliminated or significantly reduced by adjusting the manner in which the camera is being employed.

Ophir-Spiricon, LLC offers a camera recertification service. This service can help to extend the useful life of your camera and correct some point defects that may show up over time. This service can not correct cameras with serious laser damage or imager degradation. Whenever possible OSL will restore the camera to our "as new" level of certification; and if not possible, we will indicate to the user how to avoid areas of the imager that may not perform to "as new" standards.

Defects, Solutions and WorkaroundsThe following list contains examples of typical camera point defects that may occur over time, and suggested methods of compensating for them if they are troublesome:

How come I can't use the Cameras Region Of Interest (ROI) Feature in my SP503U or SP620U Camera?

Defect type Description of the Problem Recommended Solution

See Note 1 belowBright Pixel Pixels with this defect will indicate being illuminated even when no signal is present. These are the most troublesome when attempting to make accurate peak fluence and peak fluence location measurements because they represent a false signal. Most other measurements are not adversely affected by this type of defect. This type of defect is screened for during our regular camera inspection process. All pixels that exceed a set limit are corrected, if possible, before the camera ships. See Note 1 below. Our QA department will often reject cameras if the pixel can not be corrected and it exceeds our acceptance criteria.

- Ultracal/baseline correction will subtract out the defective pixel.

- Reposition the camera to remove the defective pixel from the measurement region and employ a manual aperture to isolate the pixel from the area of interest.

- Return the camera to OSL to have the bad pixel corrected and the camera re-certified.

Twinkling Pixel This is an intermittent version of the Bright Pixel defect. These often appear as the camera warms up. May disappear if the camera is run in cooler environments. Usually predicts a pixel that will soon be a permanently bright pixel defect.

These are the hardest to detect and as such may get past our camera inspection process.

Same as above.

If returned to OSL to be corrected please send a full frame data file showing the pixel as it is malfunctioning. This will aid in our ability to find and fix it.

Dark Pixel Dark pixels have low responses compared to the amount of illumination that they receive. Isolated instances of these types of defects do not pose a serious beam analysis problem and they are generally not in need of correcting. This type of defect will not significantly impact a beam measurement result unless the beam is very very small and the defect falls inside of the beam profile. Reposition the camera to remove the defective pixel from the measurement region. Dead Pixel Dead pixels have no response at all and may output a raw pixel value of zero (0) counts. This type of defect is screened for during our regular camera inspection process. All pixels that exceed a set limit are corrected, if possible, before the camera ships. This type of pixel may create a warning message when performing Ultracal operations. Ignore the warning and proceed as in the Dark Pixel case described above. Dark Clusters These dimmer than normal clusters involving about a dozen or fewer pixels are often caused by dust particles and can usually be removed by cleaning of the imager. Sometimes these can be very difficult to impossible to remove. In the latter case they are may be melted into imager

If this is the result of laser damage then imager replacement is the only solution.

These usually do not cause serious measurement problems and can be treated with the Dark Pixel workaround described above. They can sometimes be dislodged with very gentle puffs of dry air. If you return a camera to be re-certified we have a few special methods for cleaning these, but success is not 100% guaranteed. Regions of non-uniform response When large areas of an imager yield reduced signal levels this usually indicates laser damage. Long term exposure to ultraviolet radiation or overexposure to high laser power or peak energies are common causes. This type of degradation is not repairable and either the camera or the camera imager must be replaced. The initial release of the SP503U and SP620U cameras did not have the ROI feature enabled.

Why is an anti-reflection coated window required with the Pyrocam III?The Pyrocam III needs a window for protection against foreign objects entering the camera, and destroying the crystal. This could happen by someone poking a brush or Q-tip to clean off lint, etc. The window also protects the sensor from the effects of humidity. The window must have anti-reflection coating, or the two surfaces of the window will create interference fringes from a collimated light source which show up on the sensor as ripples in the beam. With anti-reflection coating the reflections, and thus the interference fringes, are minimized, and the sensor sees only the beam energy.

Customer Service QQ

Customer Hotline:

Technical Supports