Updated:2025-03-13

Views:2383

WeChat

WeChat

QQ

QQ

Online Service

Online Service

User 's Manual

User 's Manual

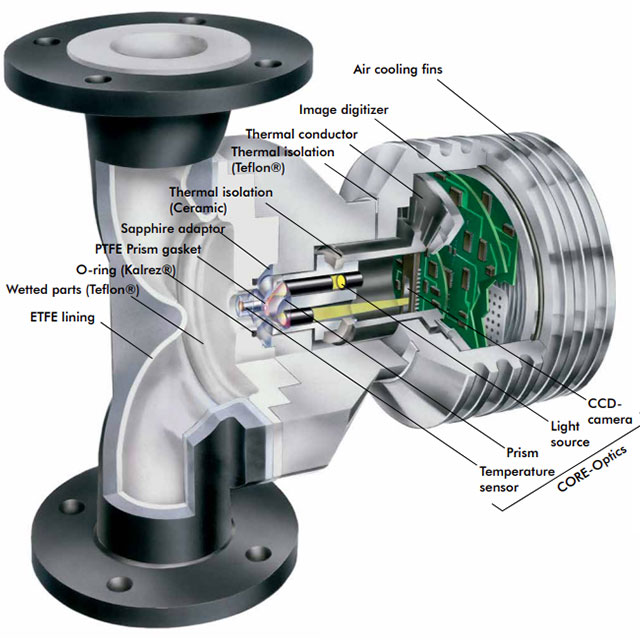

The Vaisala K-PATENTS Saunders and Teflon Bulk Online Refractometers PR-23-W and PR-23-M are designed to measure liquid concentration and density in chemically aggressive solutions and ultra-pure fine chemicals.

In demanding process control applications, the PR-23-W/M provides a highly accurate measurement technique that is independent of undissolved solids and air bubbles. The instrument can be mounted directly in the process pipe or vessel and continuously provides 4-20 mA or digital measurement signals for real-time process control.

The refractometer system consists of a Saunders main body refractometer PR-23-W or a Teflon main body refractometer PR-23-M and an indicator transmitter.

The measurement ranges from 0 to 100 Brix with a precision of +/ -0.1 Brix and a repeatability of +/ -0.05 Brix. The measurements are automatically temperature compensated over the entire process temperature range from -20°C to 130 °C and are resistant to CIP (Cleaning in situ) and SIP (Disinfection in situ) processes. An output signal of 4-20 mA proportional to the temperature compensated Brix value is provided for real-time process control.

The Saunders Seated in-line refractometer PR-23-W is designed for mass production and large pipelines (50, 80 or 100 mm diameter, respectively).

The PR-23-W comes with a Saunders (diaphragm) seat and can be installed in vertical or horizontal piping. Saunders' main material is cast iron with a solid mechanical base and PFA lining to ensure chemical resistance. Other sensor wet-parts are made of Teflon®, sapphire (Al2O3), Kalrez®, and spinel (MgAl2O4) with good chemical and mechanical resistance. The sensor cover is made of stainless steel AISI 316L.

The Teflon main Body Online refractometer PR-23-M is a compact refractometer suitable for small pipelines.

It is connected to process piping by G1/2 "concave thread or 1/2" NPT thread and can be installed in vertical or horizontal piping. The built-in flow tank is designed to prevent metal and corrosion-prone components from coming into contact with process fluids. All wet-receiving components are made of non-metallic materials, such as PTFE (Teflon®) or PVDF (Kynar®), which are corrosion resistant.

The refractometer system is dual-channel, that is, one transmitter can run two sensors. A second sensor can be easily added later.

The measurement range is 0-100% (weight percentage). The accuracy is usually ±0.1% (by weight), and temperature compensation is automatically performed during the measurement. Low and high concentration alerts can be configured.

Each sensor is accompanied by a calibration certificate, which is issued based on the comparison of a set of standard liquids with the actual sensor output. Field verification of calibration and accuracy can be performed using a certified refractive index liquid.

The calibration method is consistent for each sensor and all sensors are freely interchangeable.

Refractive index measurements range from nD 1.3200 to 1.5300, equivalent to 0 to 100% (mass percentage).

Dual channel: one transmitter can run two sensors. A second sensor can be easily added later.

Full digital system: particles and bubbles do not affect operation or accuracy.

PR-23-W sensor wet-parts: Teflon®, sapphire (Al2O3), Kalrez® and spinel (MgAl2O4) have good chemical and mechanical resistance; PR-23-M sensor wefts: Teflon® PTFE or Kynar® PVDF (polyvinylidene difluoride), prism gasket Teflon® PTFE, sapphire prism, O-ring Kalrez and sapphire adapter

Built-in Pt1000, fast temperature measurement and automatic temperature compensation work.

ATEX explosion proof, Zone 2, EX II 3 G EEx nA II T4.

ATEX explosion certification, Zone 0 and Zone 1, ATEX II 1G Ex ia IIC T4 zone classification (intrinsically safe PR-23-W-IA or PR-23-M-IA with single channel transmitter STR only).

FM explosion-proof certification,Class I, Div. 2, Groups A, B, C and D, T6. CSA certified for Class I, Div. 2.

CSA explosion-proof certification,Class I, Div. 2, Groups A, B, C and D, T4.

cCSAus electrical safety certification, sensor: Class I, pollution level is level 3; Transmitter: Class I, pollution level is level 2; The installation category is Class II.

Designed for harsh environmentsVaisala K PATENTS® Online Refractometer PR-23-W/M uses reliable CCD detector technology, also has good chemical tolerance, suitable for large production lines and small pipelines. The sensor is designed to cope with harsh process conditions, high temperatures, pressures and vibrations.

Installation and operation are simple and cost-effectiveThe online refractometer PR-23-W/M is installed in the main process line or bypass line through a Sanders seat or Teflon body.

The PR-23-W/M includes an Ethernet-based communication solution to establish a connection to computer networks and the Internet, to obtain real-time measurement data and diagnostic information through a user interface, to enable parameter changes and software updates.

The lamp or moving parts of the online refractometer need not be regularly maintained or recalibed. Users can easily achieve "install and no maintenance", which reduces the total cost of ownership.

Accurate and reliableThe Vaisala K‑PATENTS® Online Refractometer PR-23-W/M measurement technology utilizes solid-state optical elements and a CCD detector to digitally measure the refractive index. The measurement accuracy is ±0.0002 RI, which corresponds to 0.1% (percent by weight).

Due to the use of digital sensing technology, even a large number of suspended particles, bubbles, or color changes do not affect the measurement or accuracy.

Customer Service QQ

Customer Hotline:

Technical Supports