Updated:2025-03-13

Views:1831

WeChat

WeChat

QQ

QQ

Online Service

Online Service

User 's Manual

User 's Manual

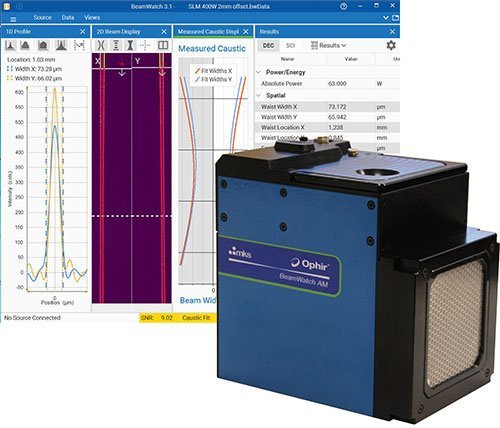

The BeamWatch AM can simultaneously measure multiple profiles of beam caustics in the camera's field of view (FOV). Real-time measurements are performed at video rates. They include:

waist (focus spot) width and location

focal shift

centroid

M2 or K

divergence

Beam Parameter Product

Rayleigh length

absolute power

ֺ Tilt angle

Real-time performance also allows for measurement of dynamic focal shift during laser startup. BeamWatch AM measurement technique is based on Rayleigh scattering of laser light by oxygen and nitrogen molecules in the air as the beam propagates through the medium. Measurement of this scattered light provides an equivalent slit-scan of the laser beam in the direction of the observed view. The scattered light is measured using a conventional camera and image capture systems. BeamWatch AM includes a camera for spatial measurements and a NIST-traceable power sensor that will provide a complete analysis of the laser power density profile

The camera is simultaneously, and real-time, viewing the beam caustic including the near/focus/and far field of the beam. This measurement technique includes Propagation and M2 measurements adhering to the ISO 11146 standards. In addition, and because all measurements are made in real-time, any focal shift occurring during the critical start up seconds is measured and reported.

| Wavelengths | 1060-1080nm |

| Minimum Focus Spot Size | 50µm |

| Power Range | 50-1000 Watts |

| Minimum Power Densities | 1.5MW/CM² |

| Beam Profiling | ISO 11146 Measurements |

| Power Meter | NIST traceable calibration ±3% |

| Compliance | CE, UKCA, China RoHS |

Why is beam profiling of the lasers in Additive Manufacturing laser systems necessary and required to be conducted at different power levels?When medical, aerospace, or other complex devices are produced in an Additive Manufacturing, powder-bed laser system, the product design requires the use of a variety of power levels. These different setting are a function of the structural integrity of the device under build, but also the efficiency of the design to avoid the use of excess materials, powders, and processing time. In a typical 1kw Additive Manufacturing laser, power levels during the build can range from 400W to 1000W, for either short or long durations. Therefore, profiling the laser beam at these different power levels is required. In a recent application test, a 1kW laser was provided at a variety of power settings from 400W to 1kW, in increments of 200Ws. The result of this diagnostic test demonstrated that as the power was increased, the ellipiticity (roundness) of the beam deteriorated. The change was not significant but demonstrated that in any build requiring a 360 degree range of the laser, the focal spot would be slightly larger in one direction and slightly smaller in a different direction, resulting in a major defect of the build. And since some of these builds can take 10’s of hours, finding out after the build that the laser is not round to specification is a costly result. These beam profiling diagnostics alerted the client to a potential problem BEFORE they went to build product, avoiding costly mistakes.

Customer Service QQ

Customer Hotline:

Technical Supports